Aircraft MRO Transformation: Key Operational Improvements

Accelerating Aircraft Production with Precision: INTERIM’s Strategic Partnership with Boeing

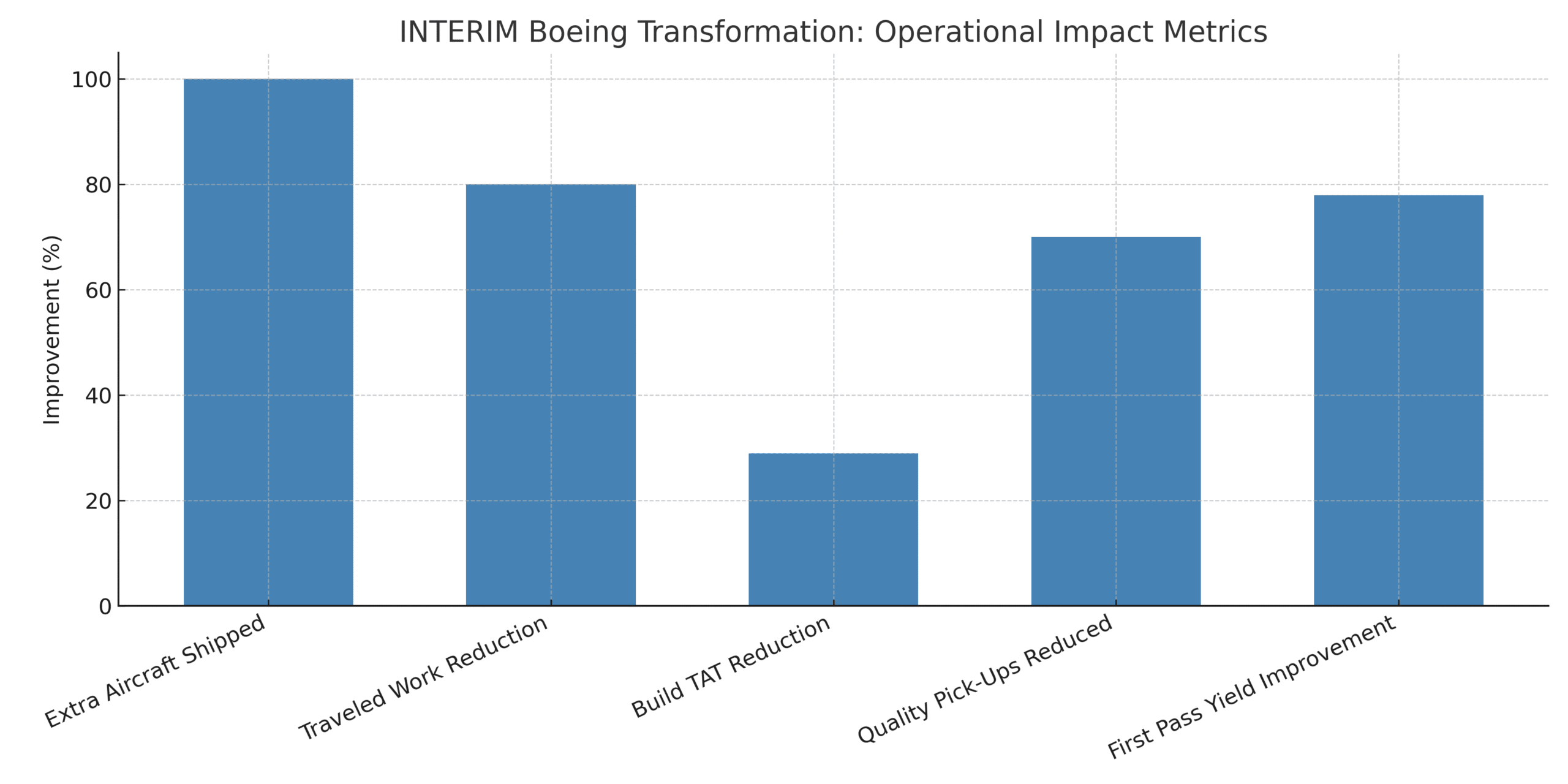

Delivering $3B+ in New Revenue and Industry-Leading Operational Gains

In a high-impact engagement with the world’s largest producer of wide and narrow body aircraft, INTERIM CEO and Business Partners led a transformative operational initiative that unlocked record-breaking throughput, reduced costs, and elevated quality. Facing gaps in workflow execution, performance accountability, and delivery speed, INTERIM embedded a team within Boeing’s operations to drive deep structural and behavioral improvements.

What We Delivered:

- Shipped 12 additional wide-body aircraft over plan

- $3B+ in incremental revenue generated

- 80% reduction in traveled work-saving ~$2M per aircraft

- Turnaround time reduced from 14 to 10 days-saving ~$500K per aircraft Quality pick-ups reduced by 70% – ~$500K in added value

- First pass yield increased to 78%

Transformation Tactics:

- Redesigned shop floor workflows for efficiency and simplicity

- Established KPI-driven accountability and daily management rhythms

- Instituted Gemba Boards and an Obeya Room structured around 9 pillars of performance

- Coached managers and supervisors to deliver consistent, measurable improvements

- Upgraded scheduling with milestone-based tracking and systematized inspections at the point of execution

“This wasn’t just a production optimization-it was a cultural evolution. INTERIM empowered Boeing teams to perform at peak velocity, with precision.”

The Bigger Picture

This transformation aligns directly with what growth leaders prioritize today: the intersection of strategy, execution, and empowered teams. INTERIM’s work with Boeing is a model for how operational vitality drives scalable and sustainable success.

Learn how we embed transformation at every level: